LED display screens have now penetrated into all aspects of our lives, whether it is outdoor large-screen advertisements, prompt information on buses, or LED mirror screens placed at the entrance of shopping malls, etc., you can see it.

The LED display can be widely used, which shows that it has many advantages. So what are its advantages and what are its disadvantages? Let’s take a look at it together.

The advantages of led display

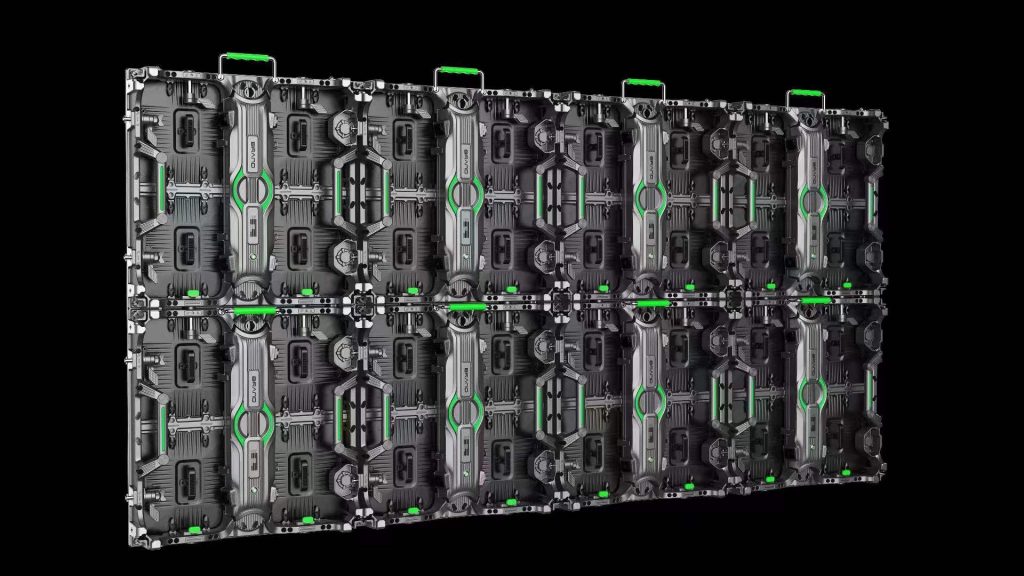

1. Unlimited and seamless stitching

The unit of the led display screen is the LED unit board, which is distributed with different sizes, different spacings, and different lamp beads. Each lamp bead is packaged by three-color chips, and is controlled by the chip behind the unit board to emit light.

If you want to assemble into a large screen, you only need to splicing multiple LED unit boards together, and there is no obstacle to splicing, the board and the board are tightly seamed, there is no frame like the LCD splicing screen, naturally there is no Patchwork troubles.

And in theory, as long as the space is large enough and the funds are sufficient, it can be spliced indefinitely.

2. Waterproof and sunscreen

The special composition structure ensures that the LED display can reach the level of waterproof and sun protection, so we can only use LED for some outdoor displays.

3. High brightness and adjustable

The brightness of the led display can be adjusted freely to meet the display needs of different light, such as outdoor facing the sun and facing away from the sun, the brightness is completely different, in order to ensure that the screen is clearly visible, it is necessary to adjust its brightness at this time.

Said so many advantages, but the LED display also has some of its shortcomings.

Disadvantages of led display

1. Low resolution

The resolution of the LED display is much lower than that of the LCD splicing screen. Even its smallest pitch products cannot be compared with the resolution of the LCD splicing screen, so the most direct consequence is that the LED cannot be viewed too close. If you look closely, you will see small squares one by one, and the picture clarity is worse.

2. Low contrast

Low contrast will lead to insufficient brightness and layers of the picture, so the presented picture will not feel good, which is not as good as the LCD splicing screen.

3. High after-sale rate

The lamp beads of the led display screen will fall off, dead lights, etc., and it is relatively troublesome to replace, especially the outdoor large screen, the maintenance difficulty is relatively high, which also increases the after-sales rate and cost.

4. Auxiliary cooling is required

If it is installed outdoors, the temperature of the LED display will sometimes be higher. In order to achieve rapid heat dissipation, an air conditioner must be installed, which is equivalent to an additional expense.

The above content is a discussion on the advantages and disadvantages of LED. In the past few years, LED display has been constantly improving, but with the advent of the production specifications that are indeed less standard, resulting in seemingly the same products, but can not match Use. Here we pick a few indicators that have the greatest impact.

(1) Maximum brightness

At the end of last year, the LED display industry proposed in the “LED International Exchange Association Standards” that there is no clear characteristic requirement for the important performance of “maximum brightness”, which is in line with the GB/T1.2-2002 standard.

Because it is mentioned in “5.4.3 Values Determined by Suppliers” of “Standardization Work Guidelines Part 2: Determination of Normative Technical Elements in Standards”: “If product diversification is allowed, certain Some characteristic values need not be specified (although these characteristics have a significant effect on the performance of the product).”.

Because the use environment of LED display screens is very different, the illuminance (that is, the ambient brightness that ordinary people call) is different, so “for most complex products, as long as the corresponding test methods are specified in the standard, the supplier shall provide a performance data. The list of (product information) is better than the specific performance requirements given in the standard”.

(2) Primary color dominant wavelength error

Change the primary color dominant wavelength error index from “primary color wavelength error” to “primary color dominant wavelength error”, which can better explain what characteristics this indicator reflects on the LED display. The dominant wavelength of a color is equivalent to the hue of the color observed by the human eye, which is a psychological quantity and an attribute that distinguishes colors from each other.

The performance requirements specified by this industry standard, literally, users cannot understand that it is an indicator that reflects the color uniformity of the LED display. Just like the aforementioned GB/T1.2-2002 (Methods for Determining the Content of Normative Technical Elements in the Standardization Work Guidelines Part 2 Standards”, one of the principles for the formulation of product standards is the “performance principle”: “As long as possible , the requirements should be expressed by performance characteristics, rather than design and description characteristics, this method leaves the greatest room for technological development.” “Primary color dominant wavelength error” is such a design requirement, if it is based on “color uniformity” Instead, there are no LEDs that define what wavelength.

(3) Duty cycle

Just like the “performance principle” mentioned above, “as long as possible, requirements should be expressed by performance characteristics, rather than design and description characteristics. This method leaves the greatest leeway for technological development.” We believe that “duty cycle” is purely a requirement of design technology and should not be used as a performance indicator of LED display product standards; we all know that any user who cares about the driving duty cycle of the display screen, they care It is the effect of the display screen, not the realization of our technology; why should we create such technical barriers by ourselves to limit the technological development of the industry?

(4) Refresh rate

Judging from the measurement method of the “Standard”, it seems that it ignores the real concerns of users, and it does not take into account the different driving ICs, driving circuits and methods used by various manufacturers, resulting in difficulties in testing. For example, the full-color screen bidding of Shenzhen Stadium, in the sample test of experts, the test of this indicator brings many problems.

We have done this test using an oscilloscope to measure the LED drive current waveform of any color to determine the “refresh frequency”, and measured 200HZ under white field; More than a dozen KHZ, but measured with PR-650 spectrometer; no matter in white field, or in gray level such as 200, 100, 50, etc., the flicker frequency of the measured light source is 200HZ.