P2 LED display screen is a small-pitch LED display commonly used indoors. Because its price is relatively favorable in the small-pitch LED display market, it is deeply loved by many people. There may be some customers who do not know what is Small pitch display, now let’s briefly introduce it.

What is a small pitch LED display?

The small-pitch LED display is that the point spacing of the LED display (the distance between the LED lamp and the lamp) is equal to or less than 2mm, which is called a small-pitch LED display, which is usually used indoors, so it is also called an indoor small-pitch LED. display.

Why do people prefer P2 for small-pitch LED displays?

This is because in the field of small spacing, the P2 indoor LED small spacing display is the minimum requirement of the small spacing series. The further down, the smaller the number of points, the higher the price of the LED display, but the clearer the corresponding picture quality. , the more beautiful the picture is.

Which type to choose mainly depends on the customer’s budget and needs. For customers with lower budgets, it is also possible to choose small-pitch products with higher points. Choose P1.875 small-pitch LED display, P1.667 small-pitch LED display, etc. with smaller number of points.

If we choose P2 small-pitch LED display, what supporting materials do we need to choose?

Material selection of supporting products for full-color led display

Lamps and Chips

The led light is also the light-emitting tube of ed. Since it is the key component of the led electronic display, it is necessary to use the LED products with reliable quality, durability and mature packaging. Only LED lamps with good stability, small discreteness, hm greater than 4000v, small attenuation amplitude, strong pressure resistance, high brightness, wavelength, and angle consistency, good light distribution effect, and resistance to temperature difference, humidity and ultraviolet rays, etc. the best.

The LED chip, also known as the IC, is the core device that controls the LED module. That is to say, once the LED chip is damaged, the entire LED module will be scrapped, which shows the importance of the LED chip. At present, only good LED chips are selected. , in order to prolong the service life of the LED module.

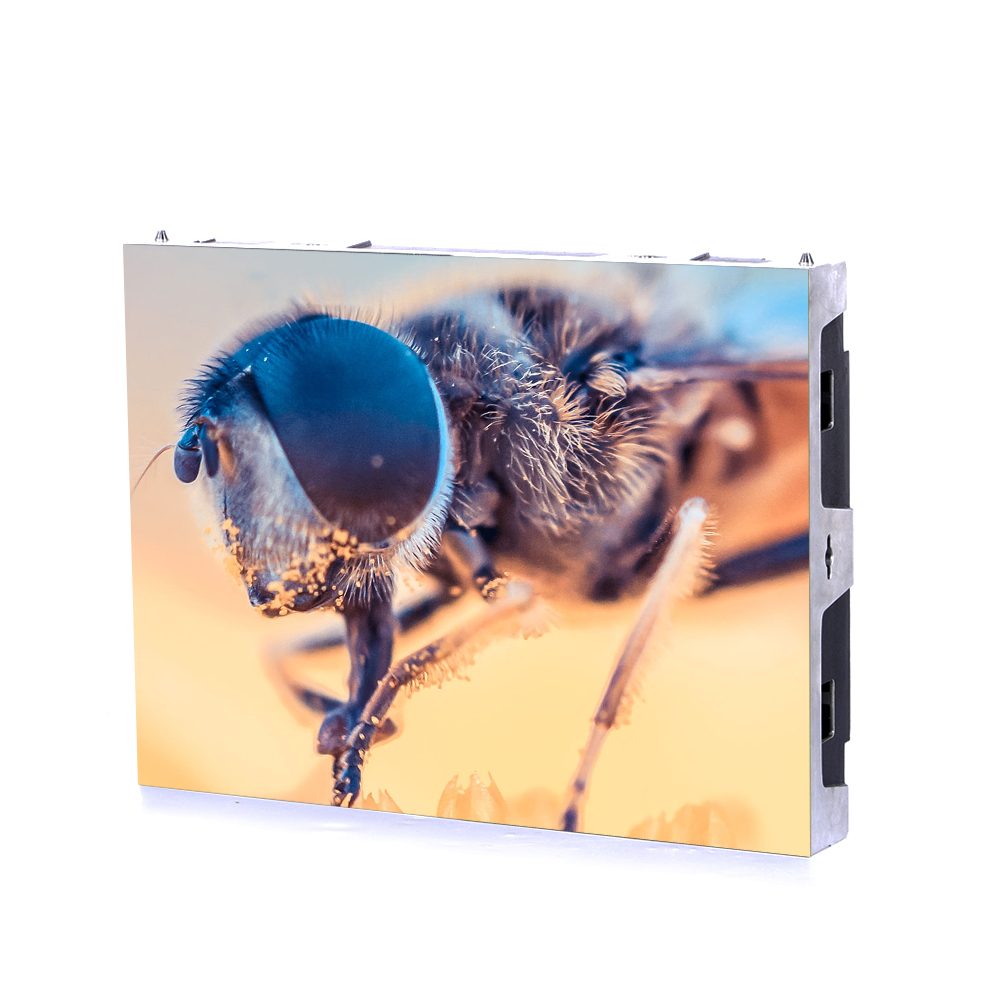

cabinet

The whole is made of steel plate or aluminum material, and the door structure is adopted. The top of the box adopts pins and the bottom adopts guide sleeves to ensure the positioning between the boxes. The overall protection of the box conforms to the ip65 standard. In addition, the structure should fully consider the heat dissipation problem. Generally, if it is used indoors, the waterproof problem is usually not considered too much. If it is used outdoors, it is necessary to add an additional waterproof function to avoid the problem of line burning due to rain erosion.

switching power supply

The power supply of the display screen adopts the well-known switching power supply module that has passed the certification. All switching power supplies have undergone strict testing, screening and aging. Ensure that the safety and quality certification requirements are fully met to meet the requirements of long-term stable and reliable operation of the display screen. under rated operating conditions. Ensure the service life is more than 10 years.

connector

The connector is an important connection device in the system. Connector products should be used to ensure the thickness of the pure gold plating of the connector and maintain the electrical connection performance. To ensure the good electrical connection performance of the system under high temperature and high humidity environment, the system can run stably and reliably for a long time.

circuit board

The circuit board is made of flame retardant epoxy material, with reasonable design and layout, and the wiring is standardized to meet the requirements of electromagnetic compatibility and circuit stability. Processing manufacturers should choose products produced by well-known manufacturers.

driver chip ic device

The drive circuit adopts the famous constant current drive chip. In a wide temperature range, maintaining high-precision constant current output and high reliability can significantly improve the uniformity and reliability of the display. The main materials of the display system should be certified by ce, fcc, ul, ccc, iso9000, etc.

I believe that if the above mentioned, adhere to reliable supporting facilities materials and professional R & D design technology, will be able to reduce the failure rate of the display, and will greatly improve the reliability and stability of the LED display.